In the rapidly evolving world of electric vehicles (EVs), few names are as prominent as Elon Musk. Known for his ambitious vision, Musk leads Tesla in a race against competitors like Contemporary Amperex Technology Co. Ltd. (CATL), the world’s largest EV battery manufacturer headed by Robin Zeng. Notably, Zeng has voiced strong skepticism regarding Musk’s ambitious 4680 cylindrical cell technology, creating a rivalry that could define the future of EV power sources.

Zeng, whose company supplies batteries for numerous EV brands, asserts that Musk’s significant investments in 4680 technology are destined to fail. During a meeting in China earlier this year, Zeng reportedly challenged Musk’s understanding of battery technology, leading to a tense exchange that left Musk “silent.” This moment not only underscores a possible gap in expertise but raises questions about the feasibility of Musk’s claims, particularly given that Tesla’s new battery format intends to deliver “five times” the energy capacity of previous cells.

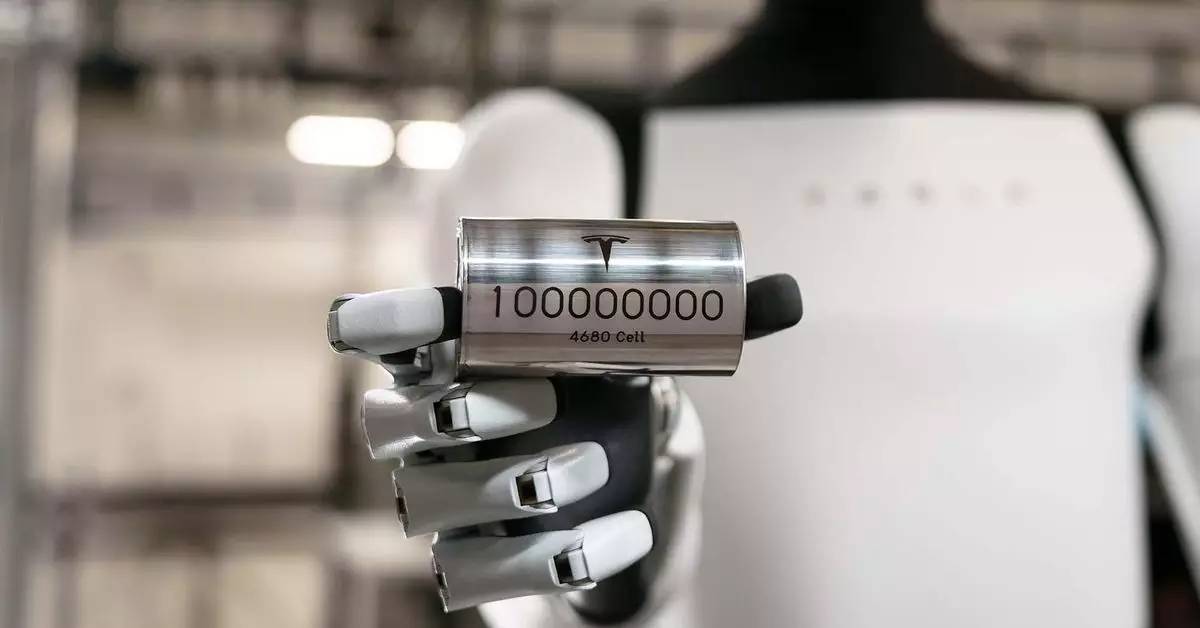

The implications of such technological advancements extend beyond mere performance metrics; they fundamentally shape the market landscape. Musk’s 4680 cells are now being utilized in flagship Tesla vehicles, including the highly anticipated Cybertruck. However, with recent reports highlighting deadlines imposed by Musk on his teams to resolve cost and production issues related to the batteries, it is evident that pressures are mounting. The complexity of battery production is not trivial, and rushing the process could have detrimental impacts on quality and safety.

In contrast, CATL boasts a track record characterized by stability and reliability. Their lithium iron phosphate (LFP) batteries are already an integral part of Tesla vehicles manufactured in China, as well as models from notable rivals like Ford. Though LFP batteries generally offer lower range compared to the cylindrical cells Musk promotes, they continue to represent a safer and more durable option. Zeng points this out as a strategic advantage, emphasizing that production capabilities should not be sacrificed on the altar of ambitious innovation timelines.

Zeng’s critique extends to Musk’s broader tendency to set unrealistic deadlines and make bold promises, particularly regarding technologies like Full Self-Driving features. This pattern of overcommitting can lead to significant skepticism among stakeholders and analysts alike. If technological breakthroughs are not delivered within the promised timeframe, it risks undermining investor confidence and tarnishing reputations within an industry that thrives on trust and accountability.

In his evaluation, Zeng acknowledges Musk’s exceptional prowess in areas like software and engineering, labeling him as a skilled innovator. Still, Zeng cautions that great ideas need to be cultivated in a manner that respects the inherent complexities involved, particularly in the demanding landscape of battery technology.

As both Zeng and Musk navigate the complex world of EV manufacturing, their discourse highlights the critical importance of technological pragmatism versus visionary ambition. The future of electric vehicles will no doubt hinge not only on groundbreaking innovations but also on the effective and realistic application of those advancements within the market. As the competition heats up, it remains essential for leaders in the industry to balance their bold dreams with the grounded realities of production and technology.