As the world shifts increasingly towards renewable energy technologies, the demand for rare-earth elements (REEs) has surged dramatically. These materials, particularly neodymium and dysprosium, play a pivotal role in high-performance magnets utilized in electric vehicles (EVs), wind turbines, and various sustainable technologies. However, the traditional methods of extracting these elements are not only energy-intensive but also environmentally taxing. Fortunately, groundbreaking research from Kyoto University has introduced an innovative solution: the selective extraction–evaporation–electrolysis (SEEE) process, which promises to enhance recycling techniques while promoting environmental sustainability.

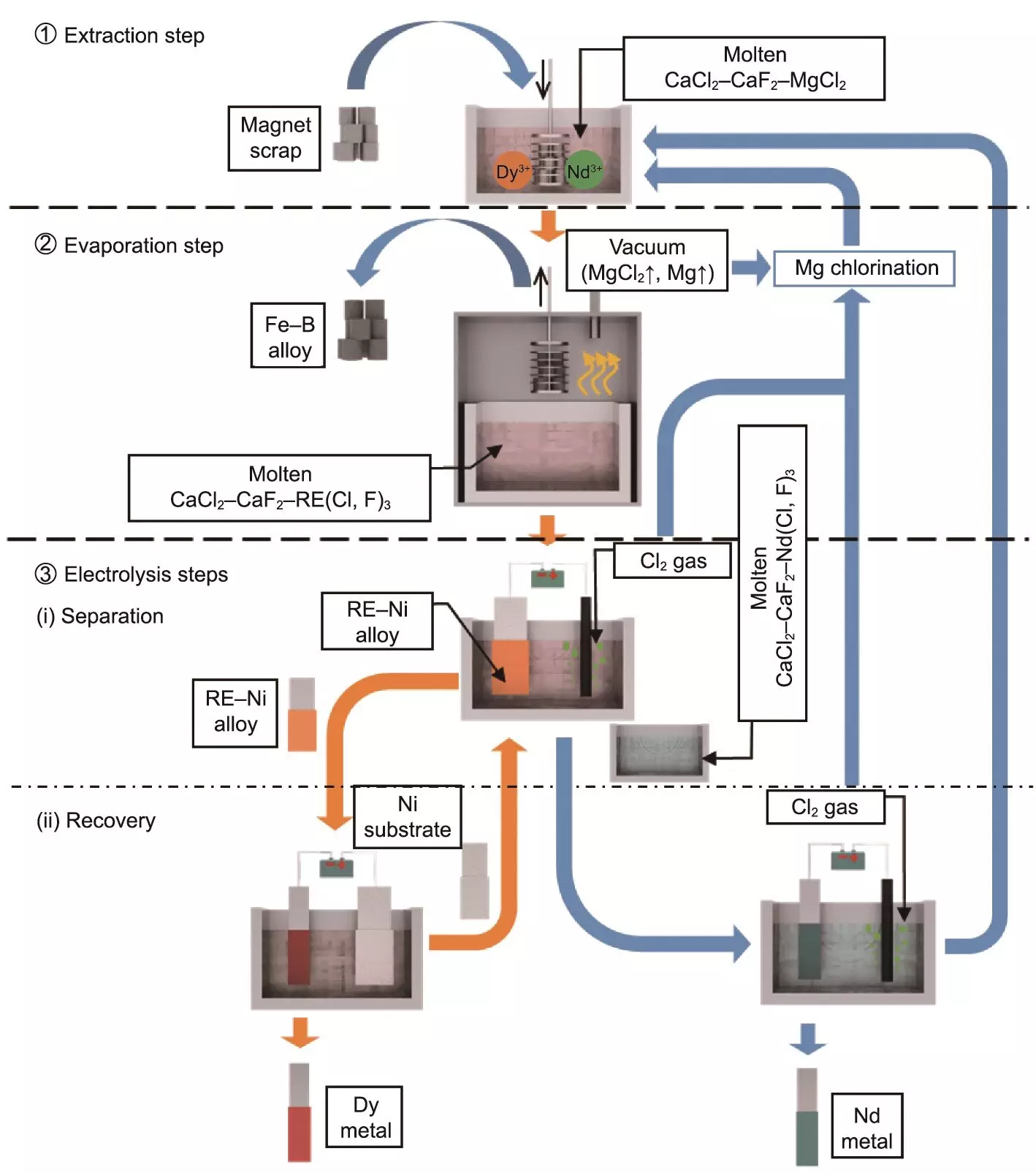

The SEEE process consists of three distinct yet interconnected stages that are designed to maximize the efficiency of rare-earth separation:

1. **Selective Extraction**: This initial phase utilizes a molten salt mixture containing calcium chloride and magnesium chloride to efficiently draw REEs from obsolete magnet scraps. The incorporation of calcium fluoride aids in managing evaporation losses, thereby significantly improving the extraction efficacy. This step is crucial as it establishes the foundation for the subsequent phases of the process.

2. **Selective Evaporation**: Following extraction, any remaining extraction agents and unwanted byproducts are eliminated through evaporation. This concentration phase increases the purity of the REEs, creating a valuable product that is ready for the final separation.

3. **Selective Electrolysis**: The final stage revolves around electrolysis, where extracted REEs are partitioned according to their formation potentials. This is a critical step since it enables recovery of neodymium and dysprosium in high purity, exceeding 90%, making the metals suitable for reuse in advanced technologies.

This tri-phased approach signifies a marked advancement over conventional recycling methodologies, offering a more sustainable and efficient alternative.

The research led by professor Toshiyuki Nohira and his team at the Institute of Advanced Energy revealed remarkable recovery rates—96% for neodymium and 91% for dysprosium. These results indicate not only the efficiency of the SEEE process but also its potential to significantly impact the REE supply chain.

As the push for electric vehicles and renewable solutions intensifies, maintaining a reliable supply of REEs becomes paramount. Relying solely on mining raises concerns over ecological impacts, thus emphasizing the urgent need for improved recycling methods. The SEEE process stands to make a difference by reducing the need for new mining activities, ultimately mitigating the environmental costs associated with traditional REE extraction.

Although the SEEE process has been specifically developed for the recycling of neodymium magnets, its potential extends far beyond just this one application. Researchers suggest that the methodology could also be adapted for other sectors, such as the reprocessing of nuclear fuels. This versatility not only paves the way for enhanced sustainability measures but also positions the SEEE process as a cornerstone technology for multiple industries, addressing various recycling and resource management challenges.

Despite the promising results from initial studies, the researchers acknowledge that further technical investigations are necessary to facilitate the full integration of the SEEE process into industrial applications. As technology and research evolve, the goal will be to refine the process and exemplify its viability across various platforms, ensuring its readiness for wider deployment.

Ultimately, as the global community takes steps towards a sustainable future, innovative approaches like the SEEE process are essential to navigating the challenges of REE recycling. The intersection of advanced research and environmental goals can drive an effective transition to carbon-neutral technologies while simultaneously addressing the pressing issues linked to material scarcity.

The SEEE process heralds a new chapter in recycling technology for rare-earth elements. By emphasizing efficiency and sustainability, this method not only addresses the urgent demand for REEs within green technology sectors but also sets a precedent for broader applications across industries. As researchers continue to iterate on this promising solution, the potential for a cleaner, more sustainable approach to resource management becomes increasingly feasible, marking a significant stride towards a greener planet.