In recent years, the construction industry has seen a significant shift towards utilizing ultra-high-performance concrete (UHPC) due to its remarkable strength and durability. However, one major challenge constraining its application is understanding how it behaves under confinement, particularly with fiber-reinforced polymers (FRP). Traditional models have effectively addressed the stress-strain relationships of normal-strength concrete (NSC) confined by FRP, but they struggle to adequately accommodate the unique characteristics of UHPC. Thus, the gap in knowledge regarding UHPC’s compressive behavior has posed a daunting obstacle for engineers and researchers alike.

A new study, driven by a team of engineers from Huazhong University of Science and Technology and Southern University of Science and Technology, aims to address this critical issue. Led by researchers S.S. Zhang, J.J. Wang, Guan Lin, and X.F. Nie, this research proposes an innovative analysis-oriented stress-strain model specifically designed for UHPC confined by FRP, providing a deeper understanding and paving the way for safer, more effective structural designs.

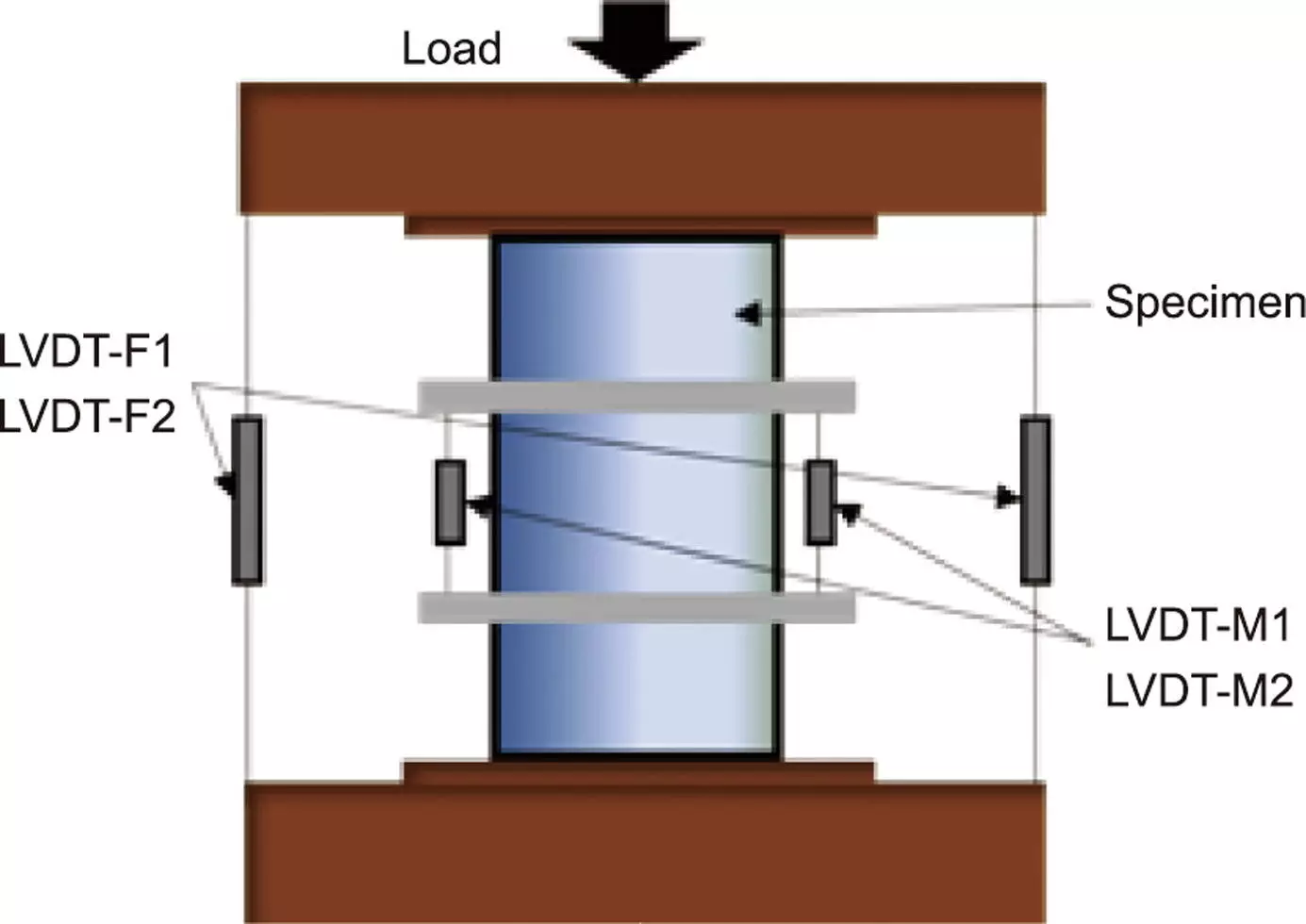

Fundamentally, the challenge lies in the failure mechanisms and compressive behavior of UHPC under concentric compression when confined with FRP. The initial research involved conducting a series of experiments to scrutinize how UHPC reacts in such scenarios. A critical realization emerged during these tests: the stress-path-independence assumptions, which are valid for FRP-confined NSC, fail when applied to UHPC. This finding necessitated a fundamental reevaluation of existing models and an expansion of theories to encompass the nonlinear characteristics of UHPC.

One of the primary revelations from the study was the tendency of FRP-confined UHPC to develop major diagonal cracks; a phenomenon that leads to non-uniform lateral expansion. This unexpected behavior results in a reduction of the effective confining pressure exerted by the FRP on the UHPC, contradicting assumptions previously taken for granted in conventional models.

In light of these new insights, the research team embarked on developing a refined model that integrates the concept of stress-path dependency. By innovating a new equation that accounts for the gap in confining pressure, the researchers successfully adjusted their analysis-oriented model to accurately represent the observed behaviors of FRP-confined UHPC.

Rigorous validation of the proposed model was achieved by analyzing a comprehensive database of test results, which demonstrated a notable improvement in accuracy compared to previous models. The new framework not only provided better predictive capabilities regarding the stress-strain behavior of UHPC under confinement but also emerged as a pivotal tool for engineers striving to innovate within the field of structural design.

The development of this model holds profound implications for the construction sector. By providing a detailed understanding of UHPC’s compressive behavior, engineers and architects can design structures that not only optimize performance but also enhance safety and longevity. The accurate predictions afforded by the new model can lead to more efficient construction processes, reducing material waste and improving overall structural integrity.

Moreover, the insights gleaned from this study herald new avenues for ongoing research. As the demands on building materials evolve and the industry increasingly seeks sustainable and high-performance solutions, the ability to accurately characterize UHPC confined by FRP is crucial. This research serves as a foundation for further studies that can explore additional applications of UHPC in innovative structural designs.

As the construction industry continues to embrace advancements in material science and engineering, this novel stress-strain model signifies a landmark advancement in the understanding of ultra-high-performance concrete. By addressing the previously uncharted complexities associated with FRP confinement, the research not only enhances the realm of structural engineering but also catalyzes innovation within concrete technology. The synergy between academic research and practical application has the potential to redefine high-performance construction, fostering the development of safer and more efficient structures worldwide.