The intersection of materials science and advanced mechanics has yielded groundbreaking revelations, especially in how common elements like silicon behave under unique conditions. Valery Levitas, a distinguished professor at Iowa State University, and his research team have been at the forefront of exploring phase transformations in silicon when subjected to combined high pressures and plastic deformation. This exploration is not merely an academic endeavor; it has significant implications for industries reliant on silicon, notably in electronics.

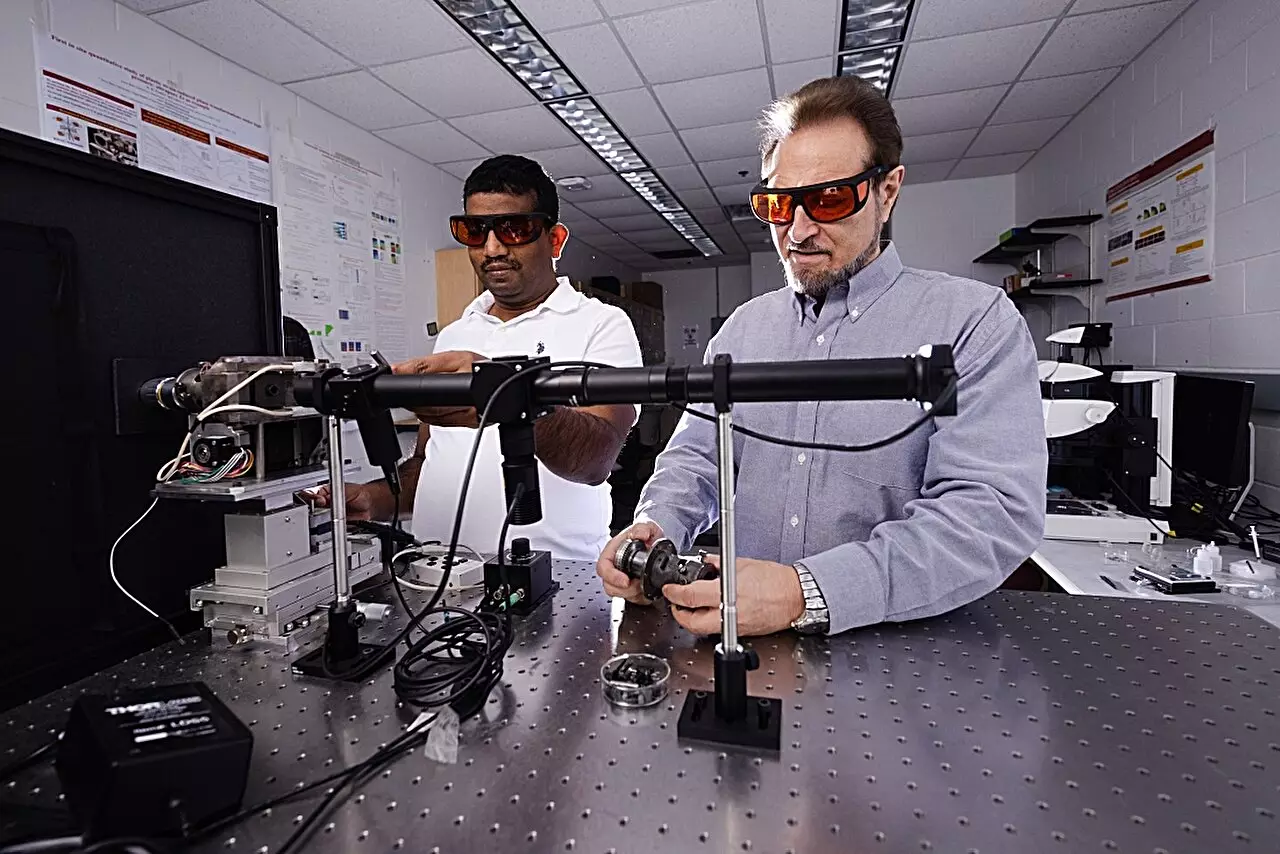

When Levitas relocated to the United States from Europe, he brought with him a state-of-the-art rotational diamond anvil cell, a device essential for understanding how materials respond to extreme conditions. The tool, designed to compress and shear materials between diamond substrates, permits researchers to observe in situ transformations of materials, thereby validating theoretical predictions about their behavior. By applying shear forces and pressure, Levitas and his collaborators can uncover how crystal structures evolve under duress, which can lead to the discovery of new phases and properties vital for creating advanced materials.

Levitas’s research emphasizes the importance of analyzing silicon, given its fundamental role in semiconductor technology. Recent findings, published in Nature Communications, provide insights into silicon’s phase transformations when subjected to substantial plastic deformations. This focus on plastic shear deformation distinguishes their work from prior studies that primarily looked at high-pressure effects alone. By systematically varying particle sizes down to the nanometer scale, they offered a comprehensive view of how silicon’s structure changes under specific conditions.

A pivotal aspect of Levitas’s study is the startling discovery that silicon’s transition from its “Si-I” to “Si-II” crystal phase can occur at pressures significantly lower than previously documented. Traditional understanding indicated that this transformation initiates at approximately 16.2 gigapascals. However, Levitas’s findings reveal that under carefully controlled plastic deformations, this transition can occur at merely 0.3 gigapascals—a reduction by a factor of 54. This breakthrough illustrates how manipulating microstructural conditions can fundamentally alter material properties without the need for extreme pressures typically deemed impractical for most industrial applications.

Levitas’s work not only challenges existing theories in material science but also opens new pathways for technological advancements, particularly in the electronics sector. Given the need for innovative materials that can function under varying environmental conditions, these insights into low-pressure phase transformations could lead to materials with tailored electronic, optical, and mechanical properties.

Another key insight from this research is the distinction between changing the shape of a material and altering its microstructure. Levitas argues that the latter is crucial for inducing phase transformations. This realization emphasizes that it is not simply about maintaining the integrity of a silicon sample but rather about manipulating it at a microscopic level to yield desirable properties. By concentrating on seven different phases of silicon, the team is investigating how each phase’s unique lattice structure can be harnessed for practical applications.

The potential for creating nanostructured composites with enhanced functionalities is one of the most exciting prospects stemming from this research. The ability to achieve desirable properties through plastic deformation rather than extreme pressures positions this research as a paradigm shift for industries where silicon is a staple.

Levitas’s work forms a cornerstone for future exploration in high-pressure and plastic deformation research, providing a framework for understanding how to control and utilize the microstructural changes in materials like silicon. By demonstrating that phase transformations can be manipulated at lower pressures, there is vast potential for applied research, particularly in fields where cost-effectiveness and material efficiency are paramount. Companies engaged in electronics manufacturing could particularly benefit from these findings, potentially leading to more sustainable practices and enhanced material capabilities.

Levitas’s innovative approach characterizes a significant advancement in material science, pushing the boundaries of how we understand phase transformations in semiconductor materials. His expectation of phase transformations at low pressures has proven to be transformative, solidifying his role as a thought leader in a field that continuously evolves at the intersection of theory and practical application. This work is set to catalyze broader innovations and holds promise for generating new materials with revolutionary applications across various industries.