This year marks a pivotal moment in the robotics industry with Boston Dynamics set to introduce its all-electric humanoid robot, Atlas, into the real-world environment of a Hyundai factory. At its core, this venture aims to integrate robotic intelligence into commercial manufacturing, positioning Atlas as a significant player in the quest for enhanced productivity. The evolution of the Atlas robot from earlier hydraulic models, which captured public fascination through their viral video demonstrations since 2013, reflects a trajectory of innovation that is increasingly focusing on versatility and efficiency.

Boston Dynamics has garnered interest not just for its impressive technology but also for its strategic acquisition by Hyundai in 2021 for a whopping $1.1 billion. This partnership hints at a future where traditional manufacturing mechanisms might be disrupted by robots capable of performing tasks that are either too strenuous or cumbersome for human workers. As Kerri Neelon, a spokesperson for Boston Dynamics, articulates, Atlas is engineered to undertake quite literally heavy tasks, such as lifting and moving awkward loads that human operators may struggle with. This shift could redefine workforce dynamics in industries reliant on manual labor.

Humanoid Robotics: A Growing Market

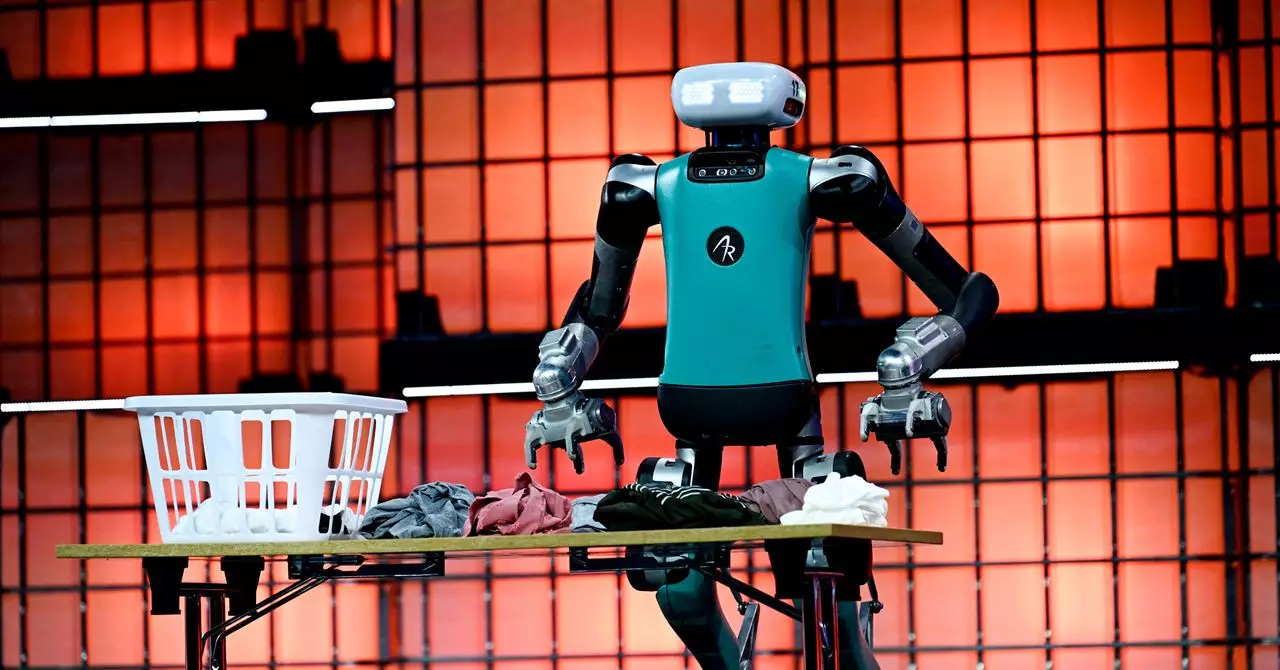

While Atlas’s deployment is on the horizon, it is crucial to acknowledge that various humanoid robots are already beginning to carve out their niches in the market. Agility Robotics’ Digit has gained traction in warehouses, moving items with agility, while Figure’s humanoid robot has started delivering its services to commercial clients as early as last year. The market is poised for explosive growth; a recent Goldman Sachs report forecasts a staggering $38 billion valuation for humanoid robots by 2035, highlighting their potential to surpass traditional robotics that have dominated the industry.

The allure of humanoid robots lies in their ability to transition seamlessly between multiple tasks. This flexibly contrasts sharply with existing manufacturing automation, which often requires bespoke setups tailored for specific operations. Jonathan Hurst, co-founder of Agility Robotics, emphasizes that while custom automation solutions may offer efficiency within narrow parameters, humanoid robots can inject adaptability into workflows that fluctuate in their demands. Such flexibility could lead to increased productivity, especially for tasks that don’t necessitate continuous operations, creating a harmonious blend of human and robotic capabilities.

Rethinking Automation in the Human-Centric World

In framing their product, Boston Dynamics highlights a “human-first” approach. With factories already optimized for safety concerning automation, the company designed Atlas to navigate environments beyond traditional factory settings. This blurring of lines between human spaces and robotic efficiency underpins a larger philosophy that the future of robotics aligns closely with human needs and workflows. Neelon’s statement, “we live in a human-first world,” serves as a clarion call for the development of technology that not only complements human labor but enhances it.

Despite the fervent optimism surrounding humanoid robots, the pathway to widespread adoption is fraught with challenges. The case of Tesla’s Optimus underscores the complexities that lie ahead. Although highly anticipated, initial demonstrations raised eyebrows when the robots appeared to require human control, stirring doubt over the technology’s autonomy. This exacerbates existing anxieties regarding robotic capabilities and public acceptance, particularly when stakeholders in the labor market feel that their jobs could be at stake.

Navigating Obstacles to Integration

Production hurdles also pose substantial challenges to the commercialization of humanoid robots. Elon Musk’s fluctuating timelines regarding mass production illuminate the impact of external factors like supply chain constraints, particularly concerning the acquisition of rare-earth metals. Such complications underline the potential risks associated with relying on advanced technologies in a globally interconnected economy.

As the robots begin to find their place on factory floors and beyond, it will become necessary to address the human element that remains integral to successful integration. The prospect of humanoid robots offers a tantalizing glimpse into a future where machines enhance human labor rather than replace it. The dialogue surrounding the coexistence of humans and machines must evolve alongside the technology to ensure a cooperative future in our increasingly automated world. This will require not only innovation but also a robust understanding of social dynamics to facilitate a smooth transition into a new era of work.